Benefits of Hard Coatings

Traditional, soft coatings, a technique commonly used for coating optical components, may soon be rendered obsolete by a higher performing coating technique known as hard coating. As detailed, hard coatings provide several advantages to traditional soft coatings.

Soft Coatings

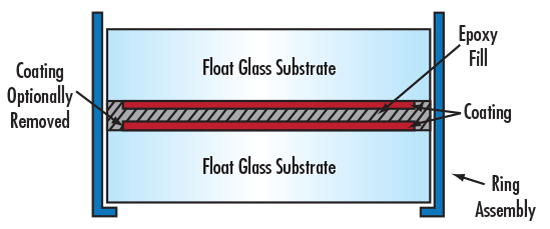

Soft coatings are multilayer thin films consisting of zinc sulfide, cryolyte, and, sometimes, silver. For traditional interference filters, the coated components are laminated together in a vertical stack to provide some protection from the environment and, typically, cored from a larger wafer. Because of the materials and manufacturing process used, soft coatings are fragile. The coating material is often removed from the edges of the filter in order to avoid degradation caused by moisture and to increase the coating’s lifetime. A diagram of the finished product is shown in Figure 1.

Figure 1: Schematic of a traditional interference filter with a thin film coating

The cost of soft coatings is maintained by the low cost of the deposition equipment, fast cycle times, and inexpensive float glass substrates, but there are high handling costs due to the sealing and ring assemblies. The cost vs. volume ratio behaves with an asymptotic trend: expensive at low volumes and stabilizing only after a few dozen 1" pieces or a handful of 2" or larger pieces are created.

Hard Coatings

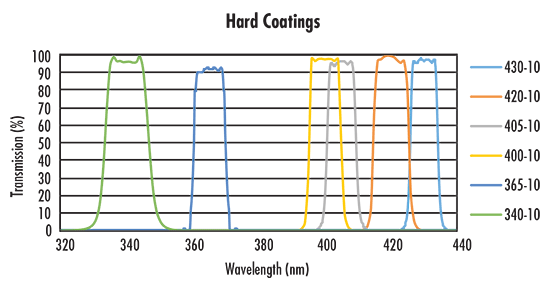

Hard coated films are developed using a plasma deposition process that provides multiple benefits compared to soft coatings. The plasma deposition process is tightly controlled using a computer, which allows for even layering, high environmental aptitude, and improved performance. For instance, not only is the transmittance of a hard coating more consistent as a function of wavelength, but it is also generally superior to the transmittance of a soft coating.

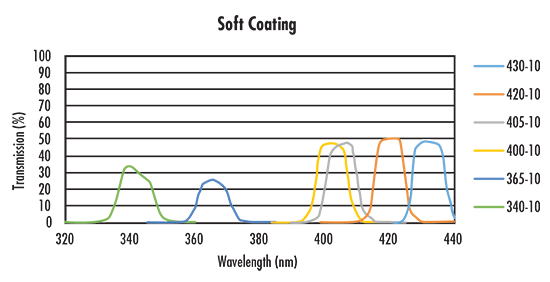

As shown in Figure 2, hard coatings can provide over 90% transmission throughout the visible spectrum and into the UV. On the other hand, soft coatings cannot achieve 90% transmission and face significant performance declines near the UV. Additionally, there are improvements with cut-on and cut-off transitions. Soft coatings have a gradual change from no transmittance to maximum transmittance, while hard coatings achieve much steeper transition.

Figure 2: Performance Comparison of Soft and Hard Coatings

Comparing the Performance of the Soft and Hard Coating Techniques | |||

|---|---|---|---|

Attribute | Soft Coating | Hard Coating | Notes |

Lifetime | 1 to 5 years | Indefiniy (under normal operating conditions) | Soft coatings are more susceptible to environmental factors, especially high humidity. These lifetimes are considered in a typical office environment. |

Temperature Stability | Averages 50 parts per million per wavelength | Less than 5 parts per million per wavelength | Soft coatings require a temperature control of ±15°C for a 1nm filter tolerance. Hard coatings can achieve less than 1 pm/°C at 1550nm much less than 1ppm/λ. |

Manufacturing Repeatability | Low | High | Compley automated processes in hard coating production allows for increased repeatability. |

Transmitted Wavefront Error | Can achieve less than λ/4 PV value | Can achieve less than λ/4 PV value | Hard coatings essentially have TWE values that equal the uncoated optic. Soft coatings have to go through extensive polishing after the lamination process. |

Cost of production | Flattens out if a large volume is made | Low due to repeatability and automated process | It is possible for hard coatings to be sold in volume at the same or lower price than their soft coating counterpart. |

Table 1: Benefit Comparison of Soft and Hard Coatings

版權(quán)所有 © 2025 江陰韻翔光電技術(shù)有限公司 備案號:蘇ICP備16003332號-1 技術(shù)支持:化工儀器網(wǎng) 管理登陸 GoogleSitemap